Generator Protection:

Generator

protection and control are interdependent problems. A generator has to be

protected not only from electrical faults (stator and rotor faults) and

mechanical problems (e.g. Related to turbine, boilers etc), but it also has to

be protected from adverse system interaction arising if generator going of out

of step with the rest of system, loss of field winding etc. Under certain

situations like internal faults, the generator has to be quickly isolated (shut

down), while problems like loss of field problem requires an ‘alarm’ to alert

the operator. Following is a descriptive list of internal faults and abnormal

operating conditions.

- Internal Faults

- Phase and /or ground faults in the

stator and associated protection zone

- Ground faults in the rotor (field

winding)

- Abnormal Operating

Conditions.

a. Loss of field.

b. Overload.

c. Overvoltage.

d. Under and over frequency

e. Unbalanced Operation e.g. single phasing.

f. Loss motoring i.e. loss of prime mover.

g. Loss of synchronization (out of step).

h. Subsynchronous oscillation.

1. STATOR PROTECTION

1.1 Differential protection for generators:

Differential protection is used for protection of the generator against phase to earth and phase to phase fault. Differential protection is based on the circulating current principle.

In this type of protection scheme currents at two ends of the protection system are compared. Under normal conditions, currents at two ends will be same. But when the fault occurs, current at one end will be different from the current at the end and this difference of current is made to flow through relay operating coils. The relays then closes its contacts and makes the circuit breaker to trip, thus isolate the faulty section. This type of protection is called the merz price circulating current system.

Confinements of this strategy:

The earth fault is constrained by the safety of the neural earthing. if The point when the fault happens is close to the neutral, this makes a minor current stream through the working relay and it is further decreased by the unbiased safety. Therefore this current is not sufficient to trek the electrical srelay. By this security plan , one can ensure just 80 to 85 percent of the stator winding.

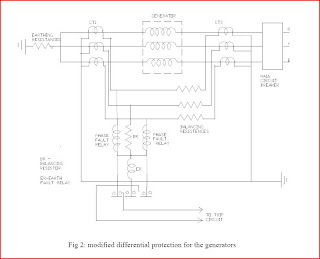

1.2 Modified differential protection:

In modified differential protection setting of the earth faults can be reduced without any effect on the stability.In this method two relays are used for the phase to phase fault and one relay is used for the protection of earth fault. In this method the two relays and the balancing resistance are connected in star and the phase fault relay is connected between the star point and the neutral pilot wire. The star connected circuit is symmetrical in terms of impedance. So when the fault current occurs due to the phase to phase fault, it cancels at the star point due to the equal impedance. Thus it is possible with this scheme to operate with the sensitive earth fault relays. Thus this scheme provides protection to the greater percentage of the stator winding.

2.6 Stator inter turn fault protection:

Differential protection for stator does not provide protection against the inter-turn faults on the same phase winding of the stator. The reason is that the current produced by the turn to turn fault flows in the local circuit between the turns involved and thus it does not create any difference between the current entering and leaving the windings at its two ends where the CTs are mounted. The coils of the modern turbo generator are single- turn , so there is no need to provide inter –turn fault protection for the turbo generator. But the inter turn protection is necessary for the multi turn generator like hydro electric generator. Some times stator

windings are duplicated to carry heavy current. In this case stator winding have two different paths.

In this type of protection primaries of the CTs are inserted in the parallel paths and secondaries are inter connected. Under the normal condition current flowing through the two parallel paths of the stator winding will be same and no current flowing through the relay operating coil. Under the inter turn fault, current flowing through the two parallel path will be different and this difference in current flowing through the operating coil

and thus causes the circuit breaker to trip and disconnect the faulty section. This type ofprotection is very sensitive.